Assembly - Engineering - Design - Prototype - Cutting - Forming - Welding - Quality Control - Finishing - Kanban

Here at Moxee we offer single-source sheet metal manufacturing products and assemblies from concept to delivery including engineering and design support, fabrication, welding, powder coating, mechanical and electromechanical assembly. Utilizing our Moxee Discovery Process we take the time to understand your specific needs relating to orders, communications, delivery requirements, quality specifications, packaging & pricing.

Moxee is a customer-oriented manufacturing company. Using automation and robotics which are supported by best-in-class engineering, manufacturing processes, quality, on-time-delivery and assembly, taking your project from design to delivery. Utilizing Moxee's Discovery process, we will work with your team to identify tolerances, critical to quality dimensions, usage and delivery requirements, cosmetic specifications and packaging to deliver a "best fit" manufacturing solution for your situation.

Below is an overview of some of the processes and services used at Moxee.

Moxee provides mechanical and electro-mechanical assemblies, testing and packaging. Moxee is equipped with the knowledge, people and equipment to do assembly work ranging from simple hardware installation, to turn-key management of complex assemblies with multi-level BOMs. Our custom made assembly lines use lean concepts including one-piece flow, visual inventory, point of use tools, two bin systems, quick changeover, mistake-proofing techniques.

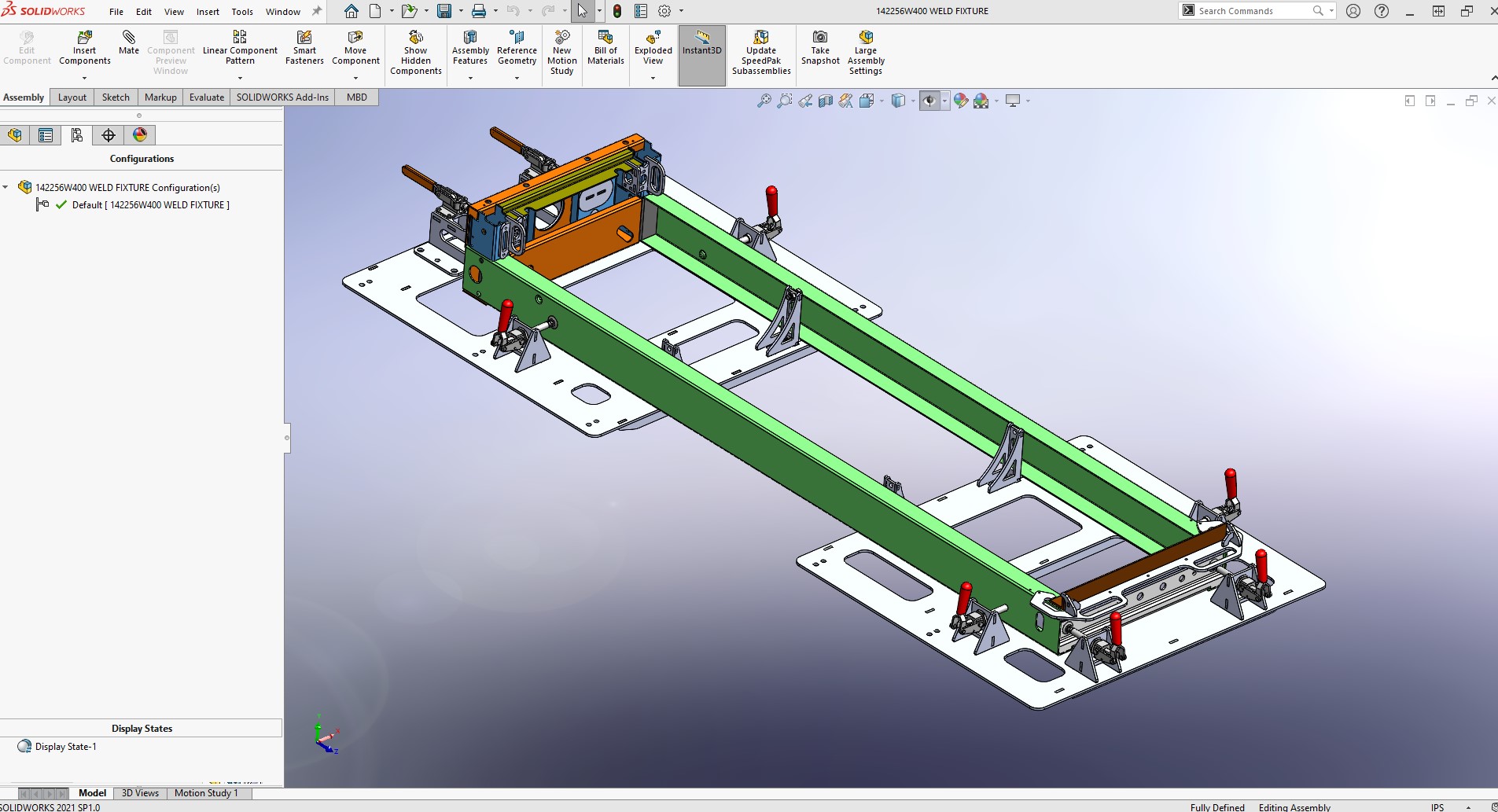

Moxee’s engineering team has over six decades of experience in sheet metal fabrication. Moxee has invested in the most up to date software available. Our team commonly engages with our customers in design for manufacturing and cost down exercises. Additionally, we will engage in reverse engineering where up to date drawings are unavailable. This combined with our dedicated prototype production line facilitates quick turn prototypes.

Current software listed below:

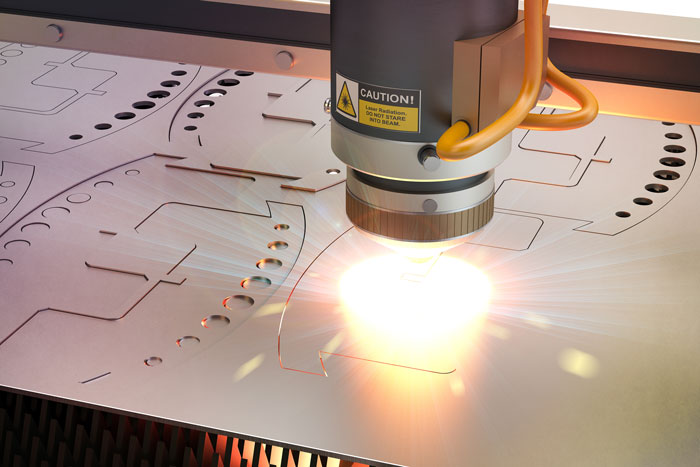

Moxee utilizes some of the best cutting equipment available. With our commitment to robotics and automation we use automatic loaders and automatic unloaders, providing us with lights out 24/7 operation.

Our cutting capabilities range from .005 to .750. However, we focus our repeatable manufacturing on .250 thickness and lower.

Moxee currently operates with 11 Amada Press Breaks ranging from 4 feet to 14 feet in length. With Amada patented Automatic Tool Changer technology. Saving tool setup times and eliminating time-consuming manual setups.

Moxee has implemented two robotic welding cells. Because of Moxee’s Engineering strength and CNC equipment, we can quickly design and manufacture high-quality, low-cost fixtures. In addition to the robotics, we have a full line of Mig, Tig, and other traditional welding capabilities.

We have recently added an automated 5 stage powder coating line, A batch line used for large parts or small quantities that don’t make sense in our automated line. Moxee also provides custom silk screening. Moxee has strategic relationships with vendors who provide zinc, anodizing, galvanize, chromate, passivate, heat-treat and wet paint.

Moxee Manufacturing and Assembly has embarked on industry leading philosophies relating to Quality. We have implemented the use of Net-Inspect Software (www.Net-Inspect.com) to assist in attaining industry leading quality. Net-Inspect works with our wireless CMM to compare first article measurement to the original prints for verification of tolerances and the creation of First Article reports. We have also used this software for the tracking of customer Return Merchandise Authorizations (RMA’s) and utilizing for internal RMA’s to better understand the total cost of quality. Due to the complexity of the software, it allows easy access to get to root cause. Additionally, we utilize the software for all our calibration requirements and machine preventative maintenance scheduling.

Through our Moxee Discovery Process we will work with the customer to put together Kan/Ban, Pull Systems, Min/Max and discreet order processing to meet your specific needs. Moxee provides assembly services in the forms of both Mechanical and Electromechanical assembly which can include Testing, Packaging and Shipping to the end customer. Packaging will be done per your specifications.

Moxee Manufacturing & Assembly is based out of Central Washington and provides Sheet Metal Fabrication and Assembly Service to OEM’s in the Northwest. With a focus on converting traditional manufacturing methodologies to automation and robotics we are leaders in customer satisfaction by providing Quality Parts On Time cost effectively.